|

|

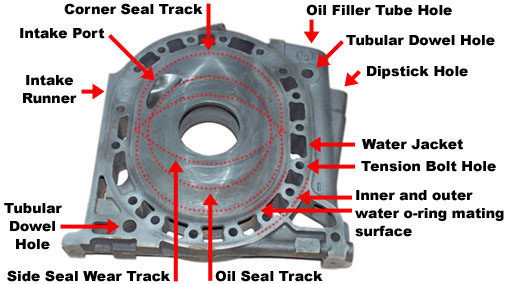

Side Housings

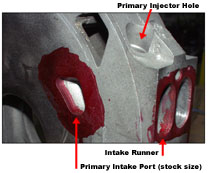

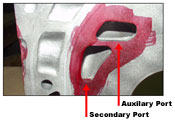

Ports in the intermediate side housing are called the Primary ports, and typically have provisions for fuel injectors through the top of the housing into the runner. Front and rear side housings also have intake ports, which are called Secondary ports. 1984, and later, 13B non-turbo engines also have a third type of port in the front and rear side housings called Auxiliary ports, which are opened by actuators for high-RPM operation to maximize top end power and closed for low-RPM operation to improve low-end torque. All turbo engines, and non-turbo engines before 1984, have only Primary and Secondary ports (two of each), so they are known as "4-port" engines. Those with Primary, Secondary and Auxilary ports (again, two of each) are called "6-port" engines. In casual use, it is not uncommon to hear the Auxiliary ports, themselves, referred to as the "6-ports", or sometimes the "5th and 6th ports".

Port size, as you can see in the above image, is limited by the tracks of the rotor oil seals and corner seals. The primary port pictured above has been enlarged from the stock size. This particular type of port enlargement is known as a "street" port, as it is both mild and keeps "between the lines". More extreme porting typically uses more creative approaches to increasing the port volume. Please refer to the "Ports" section for further information.

1985 and earlier engines had water o-ring grooves in the rotor housing and a corresponding flat mating surface on the side housings (as pictured above). Later ('86+) engines moved the groove to the side housing and the flat mating surface to the rotor housing. In practice, the only real concern is that you match rotor and side housings as to have only one side with a grove and one with the flat mating surface.